Email: info@hdfiberglass.com Whatsapp: +86 18833998929

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2022-09-07 Origin: Site

In the past more than half a century, fiber-reinforced composite materials have been widely used due to their excellent properties, and the important role of reinforcing fibers in composite materials is self-evident. Since the advent of composite materials, reinforcing fibers have undergone a transition from natural fibers to synthetic fibers.

At present, the most common reinforcing fibers include glass fibers, aramid fibers, carbon fibers, etc. This article will introduce the characteristics and applications of glass fibers for composite reinforcement.

What is fiberglass?

Glass fibers are widely used due to their cost-effectiveness and good properties, mainly in the composites industry. As early as the 18th century, Europeans realized that glass could be spun into fibers for weaving. The coffin of the French Emperor Napoleon already had decorative fabrics made of fiberglass.

Glass fibers have both filaments and short fibers or flocs. Glass filaments are commonly used in composite materials, rubber products, conveyor belts, tarpaulins, etc. Short fibers are mainly used in non-woven felts, engineering plastics and composite materials.

Glass fiber's attractive physical and mechanical properties, ease of fabrication, and low cost compared to carbon fiber make it the material of choice for high-performance composite applications. Glass fibers are composed of oxides of silica. Glass fibers have excellent mechanical properties such as being less brittle, high strength, low stiffness and light weight.

glass fiber properties

The main characteristics of glass fiber include the following aspects:

Not easy to absorb water: Glass fiber is water repellent and is not suitable for clothes, because sweat will not be absorbed, making the wearer feel wet; because the material is not affected by water, it will not shrink.

Inelasticity: Due to the lack of elasticity, the fabric has little inherent stretch and recovery. Therefore, they require a surface treatment to resist wrinkling.

High Strength: Fiberglass is extremely strong, almost as strong as Kevlar. However, when the fibers rub against each other, they break and cause the fabric to take on a shaggy appearance.

Insulation: In short fiber form, fiberglass is an excellent insulator.

Drapability: The fibers drape well, making them ideal for curtains.

Heat Resistance: Glass fibers have high heat resistance, can withstand temperatures up to 315°C, they are not affected by sunlight, bleach, bacteria, mold, insects or alkalis.

Susceptible: Glass fibers are affected by hydrofluoric acid and hot phosphoric acid. Since the fiber is a glass-based product, some raw glass fibers should be handled with care, such as household insulation materials, because the fiber ends are fragile and can pierce the skin, so gloves should be worn when handling fiberglass.

glass fiber manufacturing process

Glass fiber is a non-metallic fiber that is currently widely used as an industrial material. Generally, the basic raw materials of glass fiber include various natural minerals and man-made chemicals, the main components are silica sand, limestone and soda ash.

Silica sand acts as a glass former, while soda ash and limestone help lower the melting temperature. The low coefficient of thermal expansion combined with low thermal conductivity compared to asbestos and organic fibers makes fiberglass a dimensionally stable material that dissipates heat quickly.

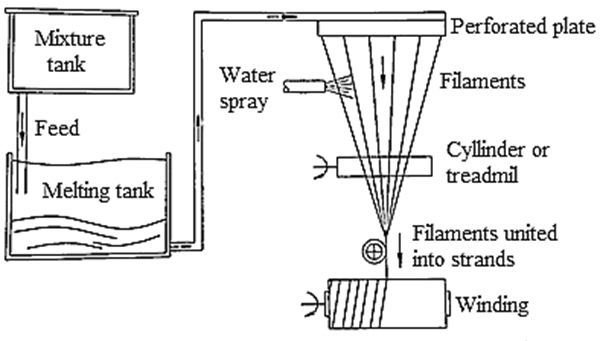

Glass fibers are produced by direct melting, which involves processes such as compounding, melting, spinning, coating, drying, and packaging. The batch is the initial state of glass manufacturing, in which the material quantities are thoroughly mixed and then the mixture is fed into a furnace for melting at a high temperature of 1400°C. This temperature is sufficient to convert the sand and other ingredients into a molten state; the molten glass then flows into the refiner and the temperature drops to 1370°C.

During the spinning of glass fibers, molten glass flows out through a sleeve with very fine holes. The liner plate is heated electronically and its temperature is controlled to maintain a constant viscosity. A water jet was used to cool the filament as it exited the sleeve at a temperature of approximately 1204°C.

The extruded stream of molten glass is mechanically drawn into filaments with diameters ranging from 4 μm to 34 μm. Tension is provided using a high speed winder and the molten glass is drawn into filaments. In the final stage, chemical coatings of lubricants, binders and coupling agents are applied to the filaments. Lubrication helps protect the filaments from abrasion as they are collected and wound into packages. After sizing, the fibers are dried in an oven; the filaments are then ready for further processing into chopped fibers, rovings or yarns.

Application of glass fiber

Fiberglass is an excellent electrical insulating material. Fiberglass fabrics have properties such as low moisture absorption, high strength, heat resistance and low dielectric constant, making them ideal reinforcements for printed circuit boards and insulating varnishes.

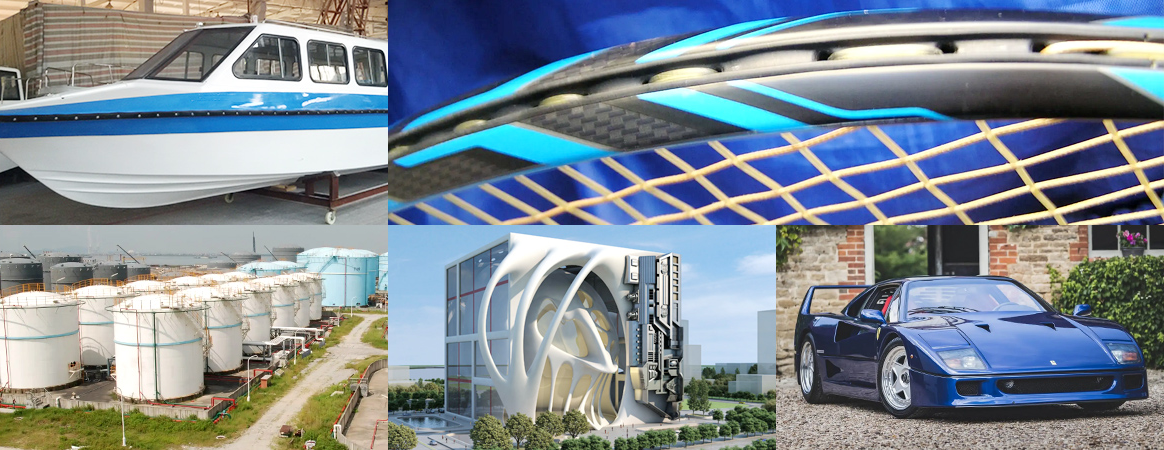

The high strength-to-weight ratio of fiberglass makes it an excellent material for applications requiring high strength and minimal weight. In textile form, this strength can be unidirectional or bidirectional, allowing flexibility in design and cost for a wide range of applications in the automotive market, civil construction, sporting goods, aerospace, marine, electronics, Home and wind energy.

They are also used in the manufacture of structural composites, printed circuit boards and various special-purpose products. The world's annual glass fiber production is about 4.5 million tons, and the main producers are China (60% market share), the United States and the European Union.

#fiberglass #glassfibra #fiberglassproperties