Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 2 Author: Site Editor Publish Time: 2024-01-31 Origin: Site

As an expert in the fiberglass manufacturing industry, I'm often approached by clients seeking insights into the best materials for their projects. Today, I'll delve into a comparison between fiberglass mesh and stainless steel mesh. Both are widely used in various applications, but understanding their differences is crucial for making informed decisions.

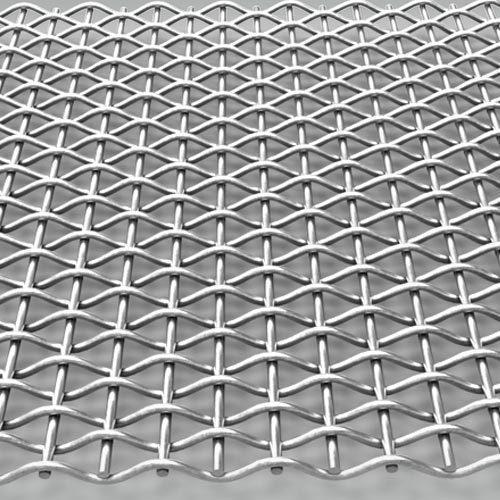

Fiberglass mesh is a versatile material made from woven glass fibers coated with a polymer resin. It's lightweight, flexible, and resistant to corrosion, making it ideal for reinforcing materials like concrete and stucco. On the other hand, stainless steel mesh is composed of interwoven stainless steel wires, offering superior strength and durability. It's commonly used in industries requiring high resistance to heat, chemicals, and abrasion.

Fiberglass wire mesh is renowned for its exceptional tensile strength, capable of withstanding heavy loads without stretching or breaking. However, stainless steel mesh surpasses fiberglass in terms of durability, especially in harsh environments where corrosion and abrasion are prevalent. While fiberglass is resistant to most chemicals, stainless steel offers unparalleled resilience against corrosive agents.

One of the primary advantages of fiberglass mesh 145g is its lightweight nature and flexibility. Unlike stainless steel mesh, which is relatively heavy and rigid, fiberglass mesh offers ease of handling and installation. This makes it ideal for applications where weight is a concern, such as lightweight construction and automotive components.

AR glass mesh finds widespread use in construction projects as a reinforcement material for concrete, plaster, and EIFS (Exterior Insulation and Finish Systems). Its high tensile strength and alkali resistance ensure long-term structural integrity. Conversely, stainless steel mesh is favored in industries such as aerospace, oil and gas, and chemical processing, where extreme conditions demand unparalleled strength and corrosion resistance.

While fiberglass mesh for concrete offers excellent performance at a lower cost compared to stainless steel mesh, the latter provides superior longevity and minimal maintenance requirements, offsetting its initial higher investment. The choice between the two depends on the specific needs of the project and the long-term cost considerations.

In conclusion, both fiberglass mesh and stainless steel mesh have their unique strengths and applications. Fiberglass excels in lightweight construction and general reinforcement needs, offering cost-effectiveness and ease of handling. On the other hand, stainless steel mesh provides unmatched durability and resilience in demanding environments, making it the preferred choice for industrial applications where strength and corrosion resistance are paramount.

As you consider your project requirements, weigh these factors carefully to determine the most suitable mesh material for your needs. Whether you prioritize cost-effectiveness or long-term performance, Hebei HaiDing Fiberglass Manufacturing Co., Ltd. stands ready to provide tailored solutions to meet your specific requirements. Reach out to us today to explore the possibilities of partnering with a trusted leader in fiberglass manufacturing.

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications