Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 0 Author: Site Editor Publish Time: 2021-08-19 Origin: Site

Reason 1: Light weight: low energy consumption and high production efficiency

The self-importance of the robotic arm should be as light as possible. The lighter the robotic arm, the smaller its movement inertia. The lightweight design can optimize the power to weight ratio of the robotic arm. Choosing lightweight materials is also an important way to achieve lightweight robotic arms. The density of carbon fiber composite material is only one-third that of steel, and it is about 30% lighter than aluminum alloy. The light weight means that the manipulator needs to consume less energy during operation, and the operation is lighter and faster. Even if the energy consumption ratio is only a little lower, or the production efficiency is improved a little, the effect of this in long-term and batch work is huge.

Reason two: high strength: more carrying capacity and diversified functions

While achieving light weight, the robotic arm must also ensure that it has sufficient load capacity. The basic weight that the robotic arm has to bear includes the weight of the arm itself plus the maximum weight of the workpiece grasped by its claws. The specific strength and specific modulus of carbon fiber composite materials are higher than those of steel, and its tensile strength is generally above 3500Mpa. 7-9 times that of steel. A telescopic carbon fiber robotic arm configured by a carbon fiber enterprise for tunnel exploration robots has a thickness of only 5 mm and a diameter of 18 cm, but it can carry up to 100 kilograms of instruments and equipment. This high load-bearing performance gives the robots Possibility of development in the direction of diversified functions.

Reason 3: Small creep:high precision and strong adaptability

Carbon fiber composite materials have minimal thermal expansion coefficient and low creep, which can adapt to working environments with large temperature differences. A rectangular telescopic manipulator tube specially equipped for electric inspection robots not only reduces its own weight, reduces energy consumption, and prolongs the work cycle exponentially, but also has stable working performance in harsh climatic environments such as severe cold and high temperature. It can complete instructions accurately and quickly, and play a huge role in replacing manual inspection work. This is also an important reason why carbon fiber composite materials are selected for robot design in many specific working environments.

Reason 4: Fatigue resistance: long life and low cost of use

Carbon fiber composite materials have good fatigue resistance. Parts made of this advanced composite material have a long service life and low frequency of maintenance or update. To give full play to the fatigue resistance of carbon fiber composite materials, we should start from the most basic design and production, because the actual fatigue resistance of carbon fiber composite manipulators is often restricted by the angle design of the composite material layer direction and the load direction. Therefore, when using carbon fiber composite materials to make a robotic arm, it is necessary to design a special production plan for the load and actual working conditions of the robotic arm.

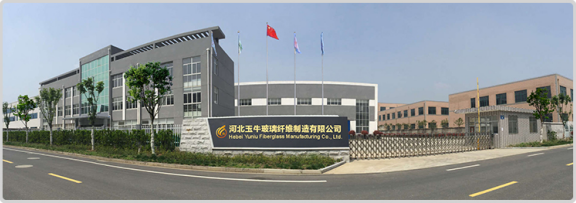

Hebei Yuniu Fiberglass Manufacturing Company Limited is a fiberglass material manufacturer with over 10-year experience, 7- year exporting experience.

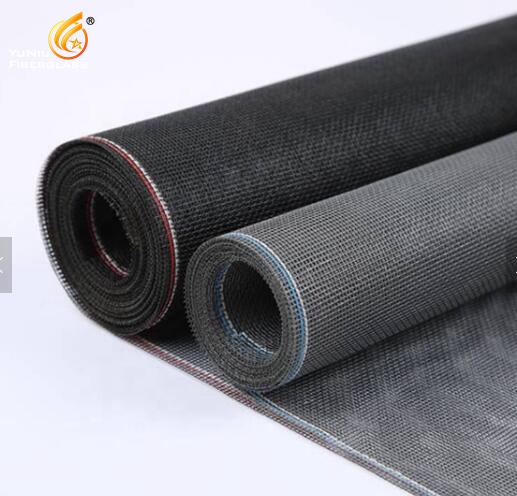

We are manufacturer of fiberglass raw materials, Such asfiberglass roving, fiberglass yarn, fiberglass chopped strand mat, fiberglass chopped strands, fiberglass black mat, fiberglass woven roving, fiberglass fabric, fiberglass cloth..And so on.

If any needs, please contact us freely.

We will do our best to help and support you.

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications