Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 4 Author: Site Editor Publish Time: 2023-05-19 Origin: Site

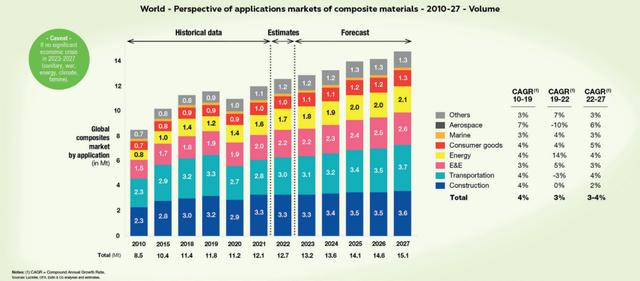

In 2020, the severe downturn caused by the Covid-19 pandemic negatively affected the underlying industries of composites (aviation, automotive, construction…). After that, the composites industry has been recovering in 2021 and 2022. According to the JEC Observer 2022-2027 recently published and established by Estin & Co for the JEC Group, the global market is estimated at 12.7Mt (composite materials used to produce composite parts) by the end of 2022. It represents a $41 billion market for composites, corresponding to a $105 billion market for assemblies made of composite parts.

Asia still leads but shows signs of slowing down

Asia should continue to lead with a compound annual growth rate (CAGR) of 4% over the next few years, followed by North America (3% to 4%) and Europe (1% to 2%).

The region is the largest market by volume, accounting for 47% of the global market, and it is also likely to grow faster than other continents, with an annual growth rate of about 4%. In Asia, the global composites market should climb to 7.3Mt by 2027, of which faibar glass Electrical and electronics (E&E) is expected to account for the majority (1.8 Mt).

“China should continue to be a strong driver of the global composites industry despite the slowdown in economic growth. For example, demand for electronics (digitization, remote working/learning…) in China and other Asian countries is expected to continue to grow,” Estin & Co Vice President Julien Deleuze pointed out.

China is already the world's largest wind energy market, accounting for 48% of the global market. Still, wind energy will account for less than 8% of China's energy production by 2021.

China's annual new installed capacity is about 30GW, accounting for about half of the new installed capacity. By 2050, the installed capacity can reach 1TW, accounting for about 26% of the total power capacity. Typically, construction in Asia should slow down due to a slowdown in the Chinese economy and its impact on the financial and real estate sectors. A default by Chinese real estate giant Evergrande in 2021 doesn't help either. The group shaking up China's financial world has been in a painful asset sale process since mid-2021. The aerospace industry has not fully recovered from the pandemic after experiencing a strong uptick in CAGR (11%) from 2010 to 2019. Still, it should grow at an 8% CAGR over the next four years. At the end of last year, China's first self-developed narrow-body passenger aircraft, the C919, made its first flight and was delivered to China Eastern Airlines in Shanghai. It is expected to be put into commercial operation this spring. The amount of composite materials reaches 11.5% of the weight of the body structure.

Transportation and Construction: Growth Drivers of the North American Composites Market

According to the forecast of the International Monetary Fund (IMF), the North American economy will grow at a rate of 2% per year in the next few years, while the future growth of composite materials should be about 3% to 4% per year

“North America and China should be strong drivers of the global fiberglass building materials industry. There is still potential for further penetration in the construction sector (maintenance and development of infrastructure such as bridges, retrofitting…), however, given the macroeconomic backdrop, new construction/equipment Some are potentially at risk,” Estin & Co. Vice President According to JEC Observer, the global composites market in the region (Marine, Aerospace, Consumer Goods, E&E, Energy, Construction and Transportation) should climb to 4.0 Mt by 2027, Construction and transport accounted for 1.3Mt and 1.1Mt, respectively. Rapidly rising mortgage rates in the U.S. are already weighing on home prices across the country. However, the North American construction industry will remain the main contributor to the composites industry, accounting for around 20% of the market, driven by large investment programs in infrastructure construction and renovation (bridges, water networks).

Aerospace companies in North America have been hit hard by the pandemic (-10% CAGR between 2019 and 2022), but seem poised to recover faster than their European counterparts, despite disruptions in the aerospace industry starting in 2020 Years ago, 2019 saw a sharp decline in annual aircraft deliveries due to difficulties with Boeing's 737-MAX.

Transport leads European composites industry

For Europe, financial institutions forecast a lower growth rate, as has been observed for the past few years, of 0-1% per annum. However, the EMEA region and the Americas together account for 63% of the global composites market in value, That's still very encouraging.

"The dynamics in Europe still vary between the different European countries, the overall growth backdrop is difficult (access to competitive energy sources, the war in Ukraine and its aftermath...). There is a lot of focus on mobility and composites can play an important role in lightweighting (Rail industry, small/light vehicles, hydrogen-heavy mobility...),” explains Julien Deleuze.

In the field of transportation, it is worth noting that composite materials are especially important for new types of vehicles (hybrid and electric vehicles, for lighter construction to compensate for heavier batteries; hydrogen vehicles, for hydrogen tanks) to improve performance, e.g. In consumer sporting goods (recycling...), composite materials account for about 16%.

Construction: A Resilient Market

The composites market for construction accounts for 19% of the global fiberglass composite materials market by value (26% by volume) in 2022. The industry was hit hard by the Covid-19 pandemic in 2020, but quickly recovered to a structural level. Therefore, the construction segment of composites is expected to grow by an average of 2% per year over the next 5 years, barring a major crisis during this period. During economic crises, infrastructure and renovation or maintenance are more resilient market drivers than new construction.

“Composite projects, while much more expensive, have become more competitive with steel, concrete and timber prices. In addition, they are much lighter and therefore require less foundation work, making composite structures more suitable for environment, and reduce the costs associated with labor and plant (machinery) hire for equivalent projects,” said a product sales manager who works for a British group specializing in Estin & Co. interviewed for the JEC Observer Road, Rail, Marine and design and manufacturing services for the coastal sector.

The poor health of infrastructure is expected to attract increasing investments in the U.S., which is likely to drive the market. Fiber reinforced polymer (FRP) rebar has the potential to replace rebar and thus poses a threat to rebar products. FRP rods are lightweight and have high tensile strength. These products can be replaced with FRP rods as they last longer and increase metalworking costs in the years to come.

There is a lot of pre-advice work on the use of these bars at European level (February 2007; CNR-DT, 2007) and at international level (ACI, 2003; CAN/CSA, 2002). Eurocodes Work is also underway to integrate the use of these glass fiber reinforcement.

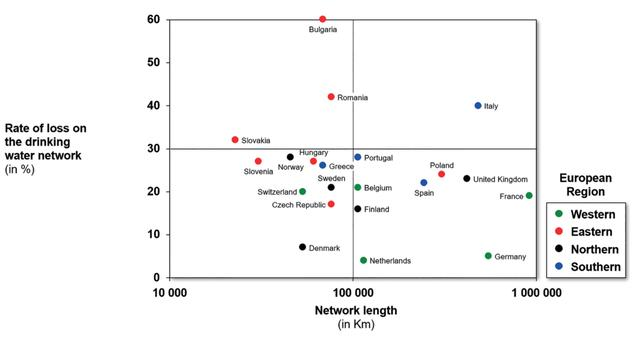

On a European level, the water supply networks in Italy and Eastern Europe (Italy, Bulgaria, Romania) offer significant opportunities for composite pipe manufacturers in the coming years. The leakage rates of these networks range from 70.000 km (Bulgaria) to 480.000 km (Italy), varying between 40% (Italy) and 60% (Bulgaria). As a result, extensive restoration work is likely to be required in the coming years.

#Composites

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications