Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 2 Author: Site Editor Publish Time: 2021-09-25 Origin: Site

NASA's "Witty" solar-powered small double-rotor drone rose from Mars at 3:34 a.m. Eastern Time on April 19, 2021. The maximum altitude of this flight was 10 feet and maintained Hovering steadily for 30 seconds, then began to descend, and landed on the surface of Mars, flying for a total of 39.1 seconds. According to the data sent back to Earth through the Perseverance Mars rover at 6:46 am Eastern Time, the UAV successfully completed its first flight mission, which is also the first powered flight on other planets. Rotorcraft.

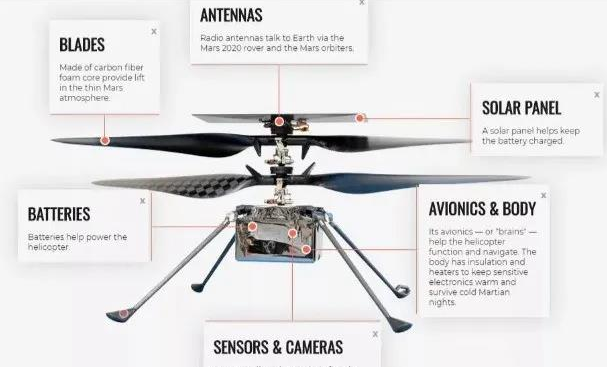

The "Giz" UAV can successfully complete its mission on Mars, which is closely related to the excellent material properties of carbon fiber composites. The domestic carbon fiber parts manufacturer Zhishang New Material provides customized services for carbon fiber parts for many drone brands. It has interpreted the basic characteristics of carbon fiber drone parts for NACA dual-rotor drones:

1. High strength, large load, ensuring super large loading.

The tensile strength of carbon fiber composite materials is 7-9 times that of steel, and the specific strength and specific modulus are far better than that of metal materials such as steel. They have been used as reinforcements in many fields. This time the "Jizhi" UAV is responsible for an extremely complex Mars survey mission. Its fuselage is loaded with basic equipment such as microcomputers, lithium batteries, sensors and cameras, as well as inertial navigation, laser altimeter, inclinometer, Accelerometers, gyroscopes and other instruments, in addition, also come with a solar panel to charge the lithium battery, in general, the load pressure is relatively large. The coaxial reverse dual-rotor propeller of the UAV is made of carbon fiber foam sandwich structure, and the four supporting legs are also carbon fiber composite materials. Thanks to the high strength of carbon fiber composite materials, it can effectively ensure the safety of all airborne objects.

2. Extremely light weight saves power to the greatest extent and prolongs flight time.

Carbon fiber material has a low density, and its specific gravity is less than a quarter of that of steel. As an advanced aviation material, it is also a "weight reduction tool" in modern industrial manufacturing. The atmospheric density of Mars is only 0.6% of that of the earth. Although the gravity of Mars is low, only 38% of that of the earth, the drone still needs enough power to leave the surface of Mars, so the drone body must be lighter. According to official information, NASA’s dual-rotor drone flying to Mars has a diameter of 1.2 meters and a height of 0.5 meters, but the weight of the drone is only about 1.8 kilograms, and the speed can reach more than 2277 rpm. Carbon fiber gives the UAV a lighter weight, thus achieving an ideal endurance. It is reported that the power source of the UAV mainly comes from solar charging, so it can fly once every Martian day, each time lasts about 90 seconds, the flight distance is up to 300 meters, and the flight altitude can reach up to 5 meters.

3. Good weather resistance and strong environmental adaptability.

Carbon fiber composite material has a small creep in a large temperature difference, is corrosion-resistant, and is suitable for use in harsh working environments. The atmosphere of Mars is very thin, only 1% of the density of the earth. It is very dry and has a low temperature. The average surface temperature is minus 55°C. Water and carbon dioxide are easy to freeze. The surface is full of sand dunes and gravel. It can be said to be a desert planet. Flying on this red planet is not easy. The body material of the drone not only has to face the low temperature but also deal with other irresistible unknown climatic factors. It is reported that the design specifications of "Giz" not only meet the standards of the spacecraft, but also can withstand the gravity and vibration generated during the rocket launch. The unique anti-radiation system and excellent material properties ensure its normal operation in the severely cold Martian environment. .

Hebei Yuniu Fiberglass Manufacturing Company Limited is a fiberglass material manufacturer with over 10-year experience, 7- year exporting experience.

We are manufacturer of fiberglass raw materials, Such as fiberglass roving, fiberglass yarn, fiberglass chopped strand mat, fiberglass chopped strands, fiberglass black mat, fiberglass woven roving, fiberglass fabric, fiberglass cloth..And so on.

If any needs, please contact us freely.

We will do our best to help and support you.

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications