Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 0 Author: Site Editor Publish Time: 2021-09-08 Origin: Site

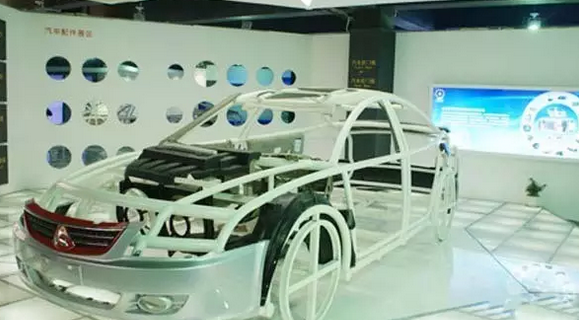

Under the background of tightening energy saving and emission reduction policies and irreversible trends in lightweight and intelligentization, new automotive materials have become a hot spot for people's attention, and the future market size may reach trillions of yuan.

Among many new materials, the application of lightweight materials such as “plastics instead of rigidity” in automobiles has become common practice. In particular, long glass fiber reinforced thermoplastics (LFT) are increasingly favored by automobile manufacturers and are widely used in automobiles, including BMW, Audi, Ford, Volkswagen and other world-renowned cars are in production.

LFT: A high-quality choice for automotive lightweight materials

It is understood that LFT refers to a glass fiber reinforced colloidal particle material obtained from a long, continuous glass fiber that is fully infiltrated by resin through a special process and then cut into a specific size. Usually the length of glass fiber is 10 to 25 mm.

As an excellent lightweight composite material, LFT has the advantages of light weight and high strength, suitable for modular design, reduced number of parts and procedures, low cost, flexible design, and corrosion resistance. It is a high-quality choice for automotive lightweight materials.

LFT materials have the following material performance characteristics: (1) Excellent mechanical properties; (2) Warpage degree; (3) Product appearance.

Products made of long glass fiber reinforced materials have glass fibers forming a three-dimensional three-dimensional network structure, which can withstand greater stress and load, and effectively absorb energy, so that the composite material can achieve more excellent mechanical properties.

Glass fiber reinforced plastic, also known as glass fiber reinforced plastic, is a new functional material made of synthetic resin and glass fiber through a composite process. It has the characteristics of light weight, high strength, corrosion resistance, and good insulation performance. As a kind of composite materials, glass fiber reinforced plastics have been widely used in related industries such as aerospace, railways, decorative buildings, home furniture, building materials and sanitary engineering due to their unique performance advantages.

Long glass fiber reinforced plastics 100 billion market is beginning to take shape

With the irreversible development trend of automotive lightweighting, the automotive industry's demand for LFT materials is liberalizing.

If the average vehicle weight is 1100kg and the use of reinforced plastics accounts for 20%, the potential market demand for long glass fiber reinforced plastics will reach 6.6 million tons by 2020. At a price of 35,000/ton, the potential market space will reach 231 billion yuan.

Hebei Yuniu Fiberglass Manufacturing Company Limited is a fiberglass material manufacturer with over 10-year experience, 7- year exporting experience.

We are manufacturer of fiberglass raw materials, Such asfiberglass roving, fiberglass yarn, fiberglass chopped strand mat, fiberglass chopped strands, fiberglass black mat, fiberglass woven roving, fiberglass fabric, fiberglass cloth..And so on.

If any needs, please contact us freely.

We will do our best to help and support you.

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications