Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 2 Author: Site Editor Publish Time: 2022-11-04 Origin: Site

Traditionally, bus and coach manufacturers have tended to use traditional materials, such as extruded aluminium profiles, rather than composite profiles, due to the lower upfront cost of the former and out of habit. However, with global fuel prices soaring in recent months, composites could offer bus operators considerable savings due to higher integrated design possibilities and lower lifetime maintenance costs.

Patrick Loock, head of the Specialty Composites Manufacturers practice, discusses the key advantages of using composite profiles over aluminium profiles in the manufacture of buses and coaches.

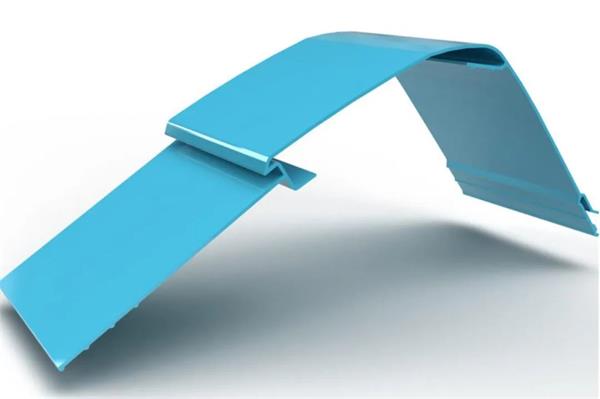

Composite profiles, in this case fiberglass, can be integrated into buses or coaches in most places where aluminium profiles are normally used. This includes internal profiles such as armrests, luggage supports and air ducts, as well as external profiles such as suspension rails, skirting and panelling.

Replacing traditional material profiles used in bus and passenger car manufacturing with composite profiles has several key advantages that can reduce a business's total cost of ownership, although the upfront costs are sometimes higher.

Reduce business cost of ownership

Composites do not have the maximum width issues faced with aluminium profiles, which means that composite bus panels can be produced from one continuous profile, rather than joining together several narrower panels to achieve the same width. Composite profiles can be up to 1.6 meters (104 inches) wide, while aluminum profiles are more limited in size. This means that the installation, replacement and maintenance of composite panels is faster, simpler and less labor-intensive than using aluminium.

The composite material profile can also be attached with a layer of release cloth during the material manufacturing process to ensure that the surface of the profile is clean and free of contamination and can be bonded at any time. Bonding the composite material to the bus in this way eliminates the need for additional rivets and screws, further reducing labor requirements.

Compared to traditional metal profiles, composite profiles have a greater choice of design flexibility in terms of profile geometry. This enables manufacturers to produce complex profiles that integrate the functions of multiple traditional aluminum components, resulting in cleaner designs that are easier to produce, require less assembly effort, and have less opportunity for human error during installation.

Additionally, composites have the added benefit of being corrosion and rust resistant, meaning they can withstand polluted or saline road conditions, unlike aluminum surfaces, which corrode over time and require regular maintenance.

Fiberglass composite profiles are also significantly lighter than their metal counterparts, which means that buses and coaches with composite components can be more fuel-efficient and thus lower carbon emissions. With the recent increase in global fuel prices, especially diesel prices, the benefits of vehicle weight reduction are particularly evident as it helps to improve fuel efficiency and reduce overall fuel costs for businesses. In addition, as the industry shifts from fossil fuels to electrification, vehicle weight reduction also helps buses and coaches achieve longer electric ranges.

The composites market is much more stable than the metal market, with less price volatility and more predictable lead times. Manufacturers that use large volumes of steel or aluminum are constrained by market conditions and, more recently, geopolitical circumstances, often without knowing the exact price or delivery date of a part before placing an order. This creates the risk of supply chain disruptions for bus and coach manufacturers and also affects profitability.

Use a continuous manufacturing process

Exel Composites specializes in pultrusion and pultrusion, both of which are continuous manufacturing processes. These processes are ideal for high-quality, high-volume production and are cost-effective for customers. Thanks to these processes, Exel is able to provide large composite profiles with a high degree of repeatability, ensuring the same quality from batch to batch.

In the pultrusion process, strands of glass or carbon fiber bundles, fiber mats, and/or technical fabrics are impregnated with resin, extruded, and fed into heated molds under external traction, in a process known as thermoset molding. heat curing.

Then cut to length. This manufacturing method supports the more flexible design options discussed earlier. For example, manufacturers can add additional reinforcing fibers to only a certain part of the profile as needed, thus avoiding wasting fibers or adding weight unnecessarily.

Given all these advantages of fiber-reinforced composite materials, fiber-reinforced composite Materials may be the key.

Lightweight fiberglass was critical to the project as it reduced operating costs and helped improve energy efficiency and environmental sustainability.

In addition, our composite profiles are resistant to deformation, chemical corrosion and harsh road conditions. Repairing fiberglass is very simple and can be done in a warehouse. This means that the overall O&M and lifetime cost of the bus will be reduced.

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications