Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 0 Author: Site Editor Publish Time: 2024-01-29 Origin: Site

Carbon fiber composite materials have always been a key direction for the country's vigorous development, and it is also a new opportunity that the capital market is paying attention to.

Opportunity 1: New application scenarios brought about by the falling price of carbon fiber, such as consumer-grade products

Features: quick opportunity, high output value, low barriers

With the large-scale release of carbon fiber production capacity in 2023, the price of carbon fiber has dropped, and even carbon fiber cloth T300 has dropped to the range of 11-14 US dollars/kg. It is expected that there is a possibility of bottoming out in the future. Therefore, more application scenarios will follow, which means that more industries can now afford the material of carbon fiber.

For example, there are cheaper carbon fiber bicycles. Now the price of carbon fiber bicycles ranges from ten thousand yuan to hundreds of thousands. In the future, we expect there will be carbon fiber bicycles with a few thousand yuan. It used to be called "black gold", but slowly it will become "the old king's swallow in front of the hall, flying into the homes of ordinary people". In this consumer-level industry, it is characterized by rapid opportunities, because as prices come down, downstream companies can immediately follow up, and the output value is also very high. This output value can easily reach tens of millions to hundreds of millions. It can come out.

But on the other hand, its disadvantage is that the barriers are relatively low, that is, if you can do it, I can do it too, which means that the barriers to entry in this industry are basically not too high.

Opportunity 2: Market areas with rapid industrial development, such as new energy vehicles

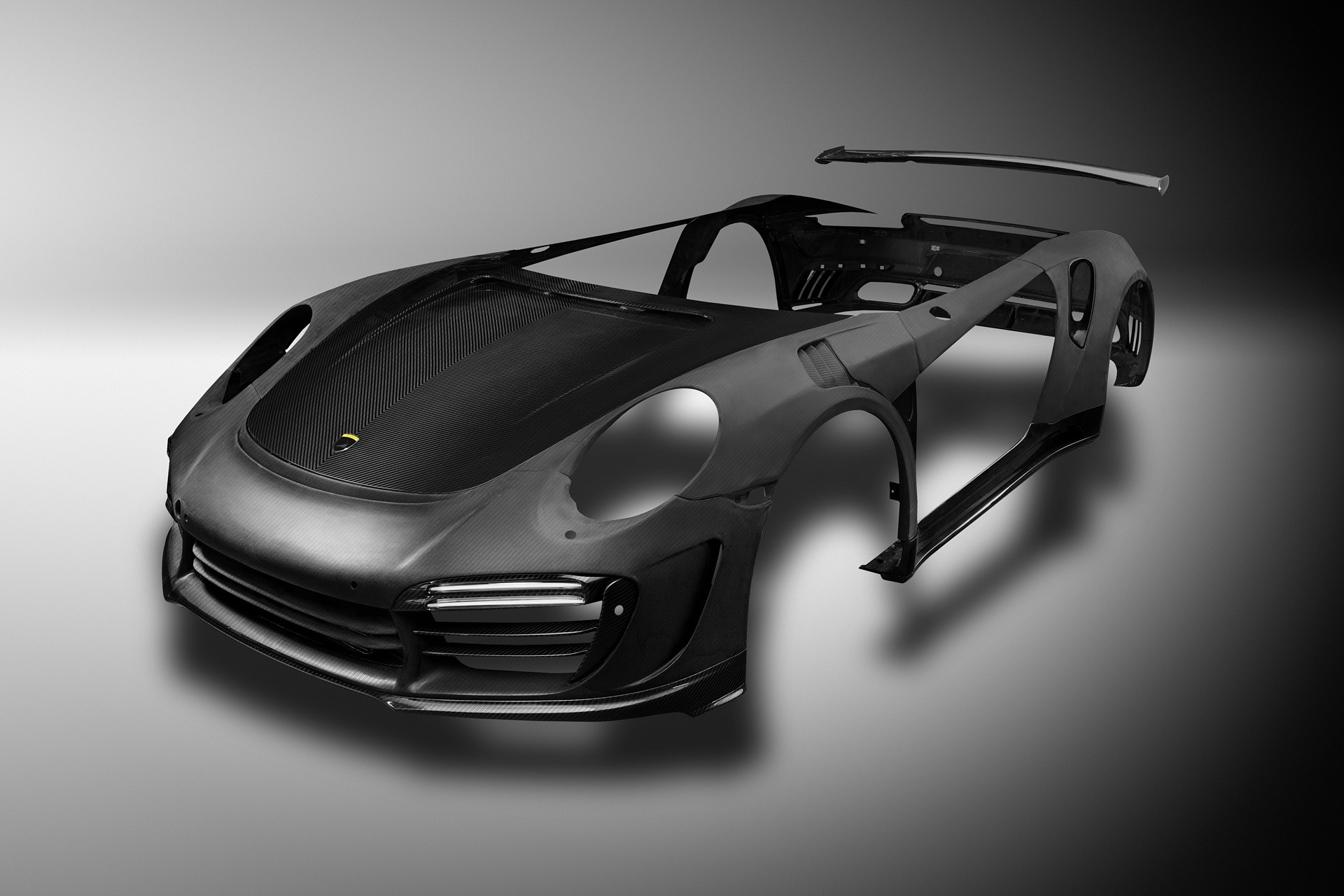

Trend: Body shell (carbon fiber material) for high-end car models | Tesla’s electronic turn

As the requirements for lightweight electric vehicles become higher and higher, the power requirements for the unit output of electric drives are getting higher and higher. Various OEMs and Tier 1 suppliers of electric drives are constantly researching new technologies to improve the unit output. To increase the output power of the rotor, increasing the rotor speed is one of the methods. We have observed that Tesla has taken the lead in using thermoplastic carbon fiber electronics. As we all know, Tesla can, to some extent, represent the direction of global new energy vehicles. There is a high probability that domestic new energy vehicles will follow suit. Keep up. We have observed that at least 5 to 10 companies in this industry have begun to move in this direction, and some have already received financing. Even if we only deal with electronic transfers, the market is not small. It can be said that the overall market is an increase brought about by the rapid development of new energy vehicles as a whole.

We have observed that my country's entire new energy vehicle production capacity has exceeded 30 million units in 2023, of which new energy vehicle production has rapidly increased to 9.587 million units. Among them, we can see that among the high-end models, BYD’s “Looking Up U9”, Haopin’s Hyper SSR, and Ji Krypton’s 001FR all use a large amount of carbon fiber composite materials as the main body configuration. We can even look forward to the main selling points of high-end cars in the future, ranging from "autonomous driving" to the configuration and material safety of carbon fiber composite materials.

Opportunity 3: Intergenerational industrial revolution brought about by disruptive technological innovations, such as thermoplastic carbon fiber/composite 3D printing

Value: high barriers, slow application, high valuation

The third is that the underlying material technology innovation brings new application scenarios, such as thermoplastic carbon fiber, which has the advantages of rapid prototyping, recyclability, and good toughness. It is a globally recognized next-generation carbon fiber technology direction. This is also the main focus of our company. Make a direction.

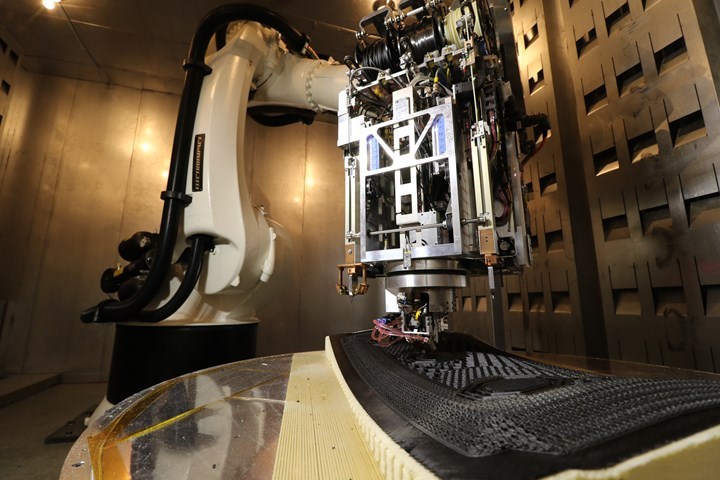

Another example is composite 3D printing technology. Why couldn’t composite 3D printing be used in the past? On the one hand, the relatively low interfacial bonding strength and mechanical properties of the materials limit their application in the field of high-performance engineering. In other words, if the performance of industrial-grade subtractive manufacturing is 100 points, 3D carbon fiber printing could only achieve 10 points in the past. But we have observed that whether Russia or the United States has achieved 50 to 60 points, then we have reason to expect that they can do better in the future, so we have better room for imagination.

However, the development and application of this type of underlying material technology will be slower, and the market needs to be gradually educated and opened. However, due to high technical barriers, once adopted, it will not be replaced for a long time and has a high profit margin. From the perspective of the difficulty of entering the industry, materials>equipment>products, therefore, the valuations of such specialized and specialized "stuck" material industries are generally very high, with an average P/S of more than 15-20 times. At the same time, this type of new material technology is also the most urgently needed technological breakthrough development direction in our country. Therefore, it also has the largest green channel for local government support and company listing.

First of all, we are optimistic about the drone track, especially the inorganic military aircraft and drone transportation. We feel very optimistic about it. And the high-end automobile industry I just talked about is a completely incremental market. I think every market mentioned here is worth tens of billions, or even hundreds of billions in the long run. The raw materials we use may cost a few hundred yuan per kilogram. For cars, it may cost several thousand yuan, and for airplanes, it may even cost tens of thousands. The profit is still very high. Of course, you also have to calculate its production costs and R&D costs. R&D costs are the bulk, and processing costs also need to be considered comprehensively.

Secondly, the industries that I personally have reservations about are the rail transit and wind power industries. As for rail transportation, since China's "three horizontal and three vertical" development of high-speed rail has ended, there will be no major increase in it in the short term. The other is the wind power industry. As soon as the twenty-year protection period for patents related to pultrusion technology expires, everyone starts to roll up. We have observed that many new companies entering the wind power industry have begun to roll out production lines in large numbers. The sharp increase in production capacity has caused market supply to exceed demand, and they will enter a price war. In the end, no one makes money. This means that incremental growth does not increase profits, so we have reservations about this industry.

For hydrogen storage bottles and supporting industries, the truly widespread use of hydrogen energy may still be 3-5 years away, so the turning point for the truly rapid development of the industry has not yet arrived. However, some people say they are very optimistic about the rapid application of hydrogen energy in China, so we will not make an in-depth evaluation because the research is not comprehensive.

#carbonfiber #composites

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications