-

Q1: Can the weight and thickness of your glass chopped strand mat be customized?

A: Sure. We can provide 100~900gsm glass fiber chopped strand mat, the greater the weight, the thicker the thickness, can be customized according to your needs.

-

Q2: Can chopped strand mat be used for both indoor and outdoor applications?

A: Yes. Its high strength, durability, and resistance to various environmental factors make it suitable for a wide range of applications, including indoor projects like insulation, wall panels, and acoustic panels, as well as outdoor projects such as roofing, waterproofing, and structural reinforcement.

-

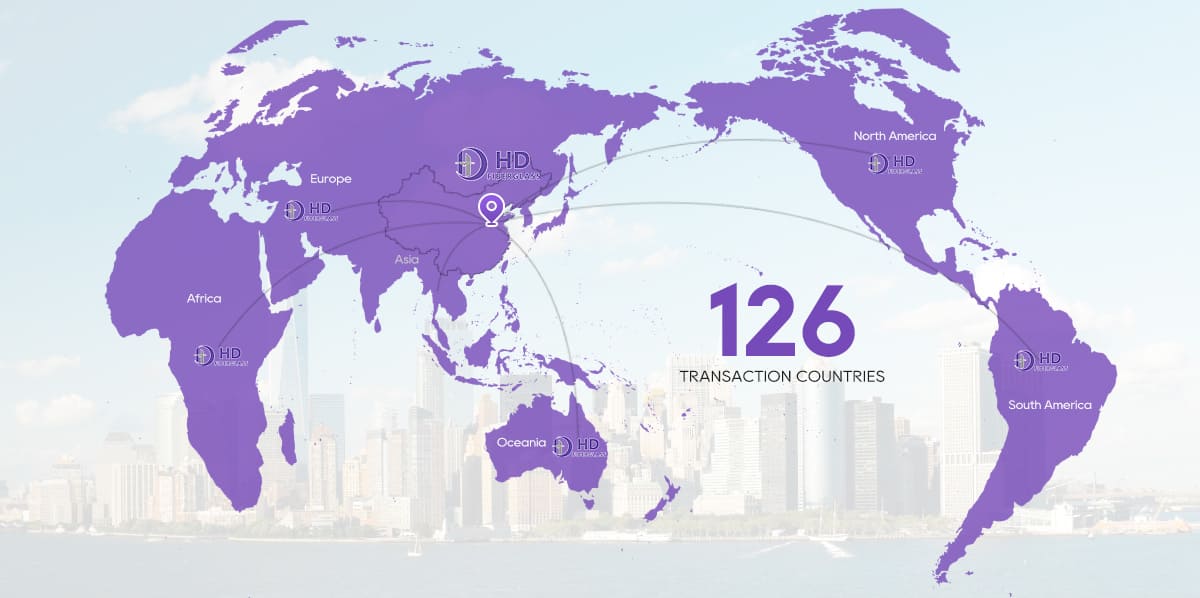

Q3: Are you a factory? Where are you located?

A: Yes, we are a manufacturer. We are located in Xingtai city Hebei province, China.

-

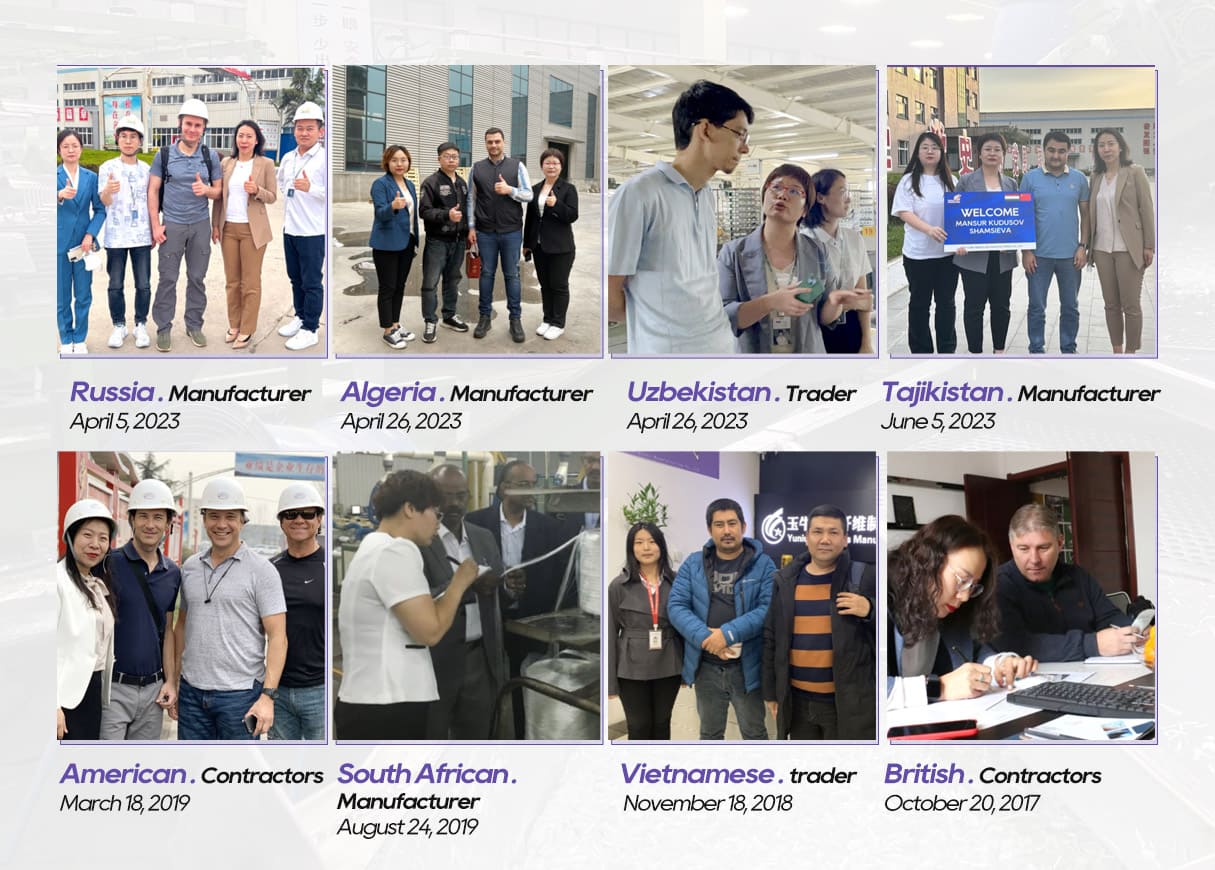

Q4: Can I come to China for factory inspection?

A: Of course, you are welcome to visit our factory and company at any time.

-

Q5: How long does it usually take for me to receive the goods?

A: Depends on whether you want to do customization your chopped strands or not, and also depends on the speed of customs clearance and logistics, but we can guarantee to ship regular chopped fiberglass in less than 2 business days, and we have customers in Singapore who received the goods in less than 2 weeks.

-

Q6: When can I offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price please call us or tell us in your email , so that we can reply you priority.

-

Q7: How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but you need to pay the freight charge.If you need a special size, We will charge the sample making fee which is refundable when you place an order.

-

Q8: What are the payment options?

A:You can use Western Union, which has a lower fee, or PayPal if you can accept a slightly higher fee, but please note that for new customers, we only accept the 30% T/T of the payment, or if you have been with us for years and run into cash flow pressure, we do offer OA credit.

-

Q10: If I buy a large quantity of fiberglass mat, how do I storage and handling practices of it?

A: The recommendation for fiberglass mat is to store it in a dry, well-ventilated area to protect it from moisture and contamination. Wear appropriate personal protective equipment such as gloves and goggles when handling this material.