Email: info@hdfiberglass.com Whatsapp: +86 15200033566

Views: 0 Author: Site Editor Publish Time: 2023-02-08 Origin: Site

Carbon fiber + wind power

A number of studies at home and abroad have shown that carbon fiber reinforced composite materials can exert the advantages of high elasticity and light weight in large wind power blades. The larger the external size of the blade, the more obvious this advantage is. Compared with glass fiber materials, the weight of blades made of carbon fiber composite materials can be reduced by at least 30%. The reduction in blade weight and increase in stiffness is conducive to improving the aerodynamic performance of the blades, reducing the load on the tower and the axle, and making the wind turbine more stable. The power output is more balanced and stable, and the energy output efficiency is higher. If the electrical conductivity of carbon fiber materials can be effectively utilized in structural design, damage to the blades caused by lightning strikes can be avoided. Moreover, carbon fiber composite materials have good fatigue resistance, which is conducive to long-term work of wind blades in harsh weather conditions.

Carbon fiber + lithium battery

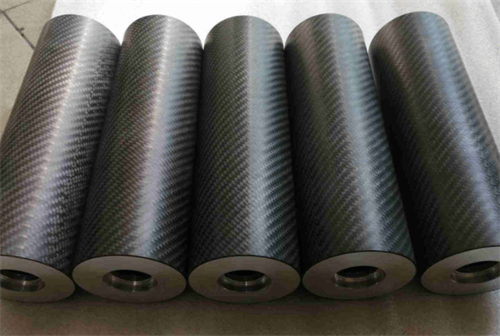

In the manufacture of lithium batteries, a new trend has been formed to replace traditional metal rolls with carbon fiber rolls on a large scale, oriented to "energy saving, emission reduction and quality improvement". The application of new materials is conducive to increasing the added value of the industry and further improving Product market competitiveness. At present, carbon fiber rollers have made a comprehensive breakthrough in the field of lithium battery manufacturing.

German manufacturer SGL Carbon and NIO have developed a prototype carbon fiber reinforced plastic (CFRP) battery enclosure for electric vehicles that is around 40% lighter than its aluminum counterpart. According to reports, the use of composite materials in the battery housing system, especially high-performance carbon fiber, can enable the vehicle to achieve better dynamic performance and obtain a very high energy density of the battery pack (over 180 Wh / kg), thereby increasing the cruising range.

Carbon Fiber + Photovoltaic

The characteristics of high-strength, high-modulus, and low-density carbon fiber composite materials have also received corresponding attention in the photovoltaic industry, among which carbon-carbon composite materials are the most used in carbon-carbon thermal fields.

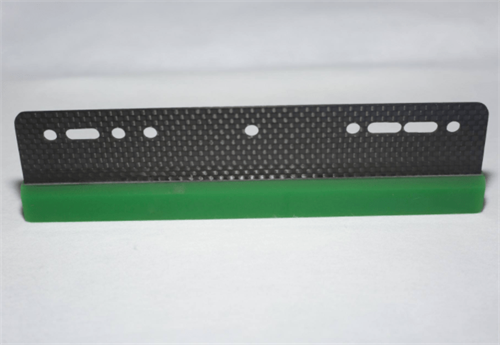

The application on some key components is also gradually advancing, such as the use of carbon fiber composite materials to make silicon wafer brackets. Another example is carbon fiber squeegee film. In the production of photovoltaic cells, the lighter the squeegee film, the easier it is to make finer, and a good screen printing effect has a positive effect on improving the conversion effect of photovoltaic cells.

Carbon Fiber + Hydrogen Energy

For the 2022 Beijing Winter Olympics, the first batch of hydrogen energy commuter buses jointly developed by Yutong Group and SPIC Hydrogen Energy Company will serve the urban area of Beijing. The three competition areas of Yanqing and Zhangjiakou in Beijing will use 165L hydrogen storage cylinders, which can be filled in 15 minutes. The designed cruising range of hydrogen can reach 630 kilometers, and it can go back and forth three times. It can also operate normally at a low temperature of minus 30 degrees. This time, the hydrogen energy vehicle, from materials, components to systems, is all localized and self-produced. The hydrogen-powered generator system, after the electrochemical reaction of hydrogen and oxygen, releases 100% pure water, which is comparable to traditional vehicles. Compared with hydrogen energy batteries, the energy conversion rate is as high as 60%-80%, which is 2-3 times that of internal combustion engines. Hydrogen is produced by wind power and photovoltaic renewable energy, taken from nature and returned to nature, truly achieving zero carbon emissions.

#carbonfiber #application

Is it better to choose emulsion or powder for glass fiber chopped strand mat?

Building Stronger Ships: Application Cases And Technical Advantages of Yuniu Chopped Glass Fiber Mat

Yuniu Fiberglass Chopped Strand Mat - Helping Your Project To Success

Corporate Visual Identity of Hebei HaiDing Fiberglass Manufacturing Co., Ltd.

What does the price increase of fiberglass products (chopped strand mat) mean?

Fiberglass Materials for Electrical Insulation and Electronics Applications