Email: info@hdfiberglass.com Whatsapp: +86 18833998929

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Unit weight: | |

|---|---|

| Availability: | |

| Quantity: | |

YN-FMF-001

Yuniu fiberglass

2020-19-001

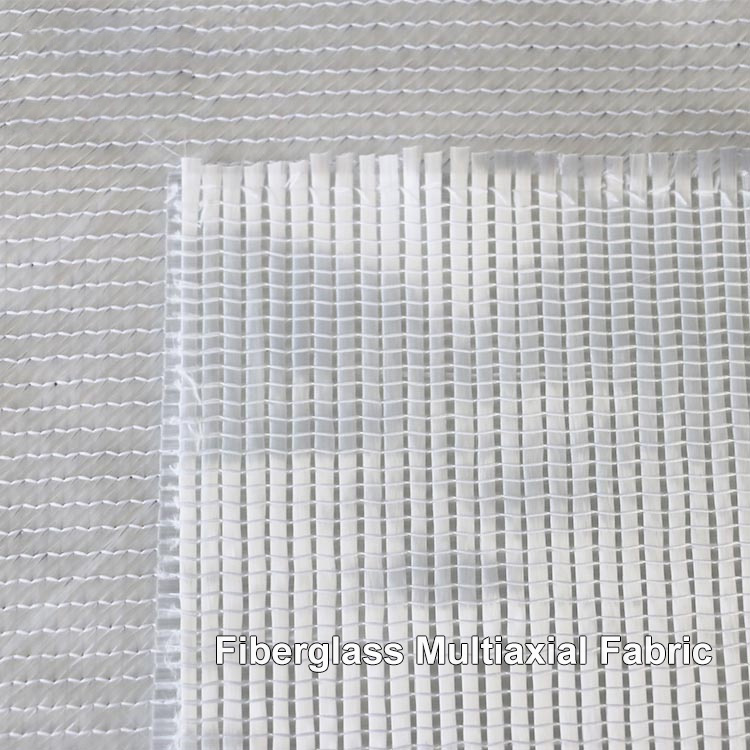

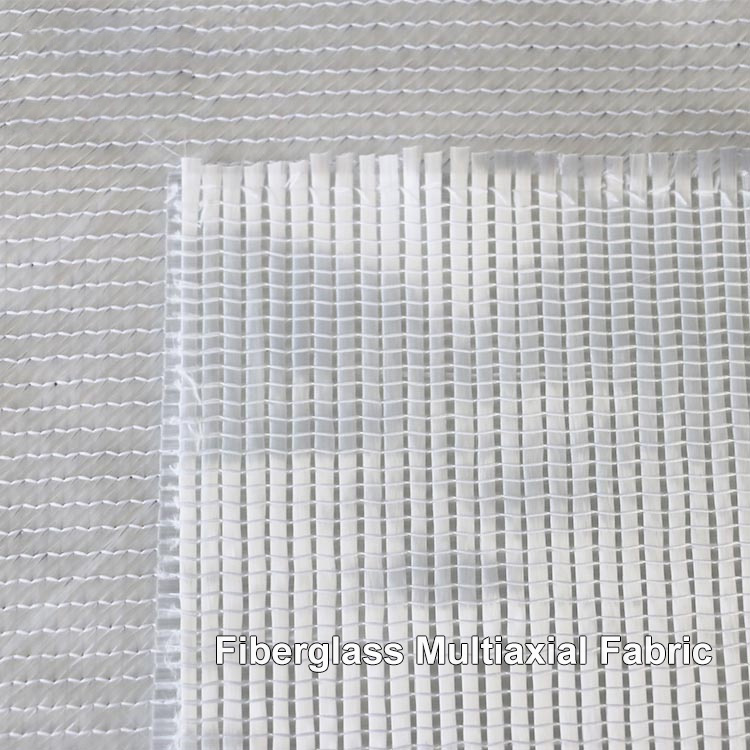

fiberglass multiaxial fabric for boat building new product woven fiberglass cloth

Description:

Multi-Axial Fiberglass Fabric is a type of composite reinforcement material used in various industries, particularly in manufacturing composite structures. This fabric is characterized by its multi-axial construction, meaning it consists of layers of fiberglass fibers oriented in different directions.

The multi-axial construction of the fabric offers significant advantages in terms of strength and stiffness. The fibers are oriented in multiple directions, typically at 0°, 90°, and ±45° angles, which enhances the fabric's ability to withstand different types of loads, including tension, compression, and shear forces. This multidirectional reinforcement improves composite components' overall structural integrity and load-bearing capacity.

The 1708 Multi-Axial Fiberglass Fabric is commonly used in the construction of high-performance composite parts, such as boat hulls, automotive components, wind turbine blades, aerospace structures, and sporting goods. Its versatile nature allows for tailored reinforcement in specific areas, optimizing strength and minimizing weight.

Overall, the Multi-Axial Fiberglass Fabric is a reliable and widely used material in the composites industry, providing enhanced strength, stiffness, and versatility for a variety of applications.

Application:

It's compatible with UP,Vinyl Ester and Epoxy etc,used in GRP pultrusion process,hand lay-up process and RTM process etc,out-made products include GRP boats,automobile parts,wind energry blades etc.

How To Use Multi-Axial Fiberglass Fabric?

Prepare the surface: Ensure that the surface where the fabric will be applied is clean, smooth, and free from any contaminants that could affect adhesion or integrity.

Cut the fabric: Measure and cut the fabric to the desired shape and size using sharp scissors or a rotary cutter. Consider the specific requirements of your project and cut the fabric accordingly, allowing for any overlaps or seam allowances as needed.

Position the fabric: Place the cut fabric onto the prepared surface, aligning it with the desired orientation and direction of the fibers. The multi-axial construction of the fabric allows you to position it in various orientations to best suit your project's structural needs.

Apply resin: Once the fabric is properly positioned, impregnate it with an appropriate resin system. Commonly used resins include polyester, epoxy, or vinyl ester resins. Follow the instructions provided by the resin manufacturer regarding the mixing ratios, pot life, and application techniques.

Wet out the fabric: Apply the resin onto the fabric using a brush, roller, or squeegee, ensuring thorough saturation of the fabric. Work the resin into the fabric, ensuring that all layers are impregnated evenly. Take care to avoid excessive resin pooling or dry spots.

Consolidation and removal of air bubbles: After wetting out the fabric, consolidate the layers by using a consolidation roller or by applying vacuum pressure if applicable. This helps to remove any trapped air bubbles and ensures proper bonding between the fabric and the substrate.

Cure the composite: Allow the resin to cure according to the manufacturer's instructions. This may involve a specific curing time and temperature. Ensure proper curing conditions, such as temperature control and appropriate curing duration, to achieve optimal mechanical properties.

Post-processing: After the composite has cured, you can further process it as required. This may include trimming excess material, sanding or finishing the surface, or applying additional layers or coatings depending on your project's specifications.

Remember to follow safety guidelines, wear appropriate personal protective equipment, and consult the specific instructions provided by the fabric and resin manufacturers for best results.

General Specifications And Key Technical Data:

Specs | 0º(g/m2) | 90º(g/m2) | +45º(g/m2) | -45º(g/m2) | Mat(g/m2) | Total Weight(g/m2) |

EMF400/800(0º, 90º) | 400 | 400 | ---- | ---- | 400 | 1200 |

EMF1200(0º, +45º, -45º) | 400 | ---- | 400 | 400 | ---- | 1200 |

EMF800(0º, 90º, +45º, -45º) | 200 | 200 | 200 | 200 | ---- | 800 |

EMF450/800(0º, 90º, +45º, -45º) | 200 | 200 | 200 | 200 | 450 | 1250 |

Products feature and Advantages:

1)Mechanical property of different directions is adjustable.

2)The multi-layers structure could simplify forming process,improve operation efficiency.

3)Quickly wet-out,good molding property,easily to delete air bubbles.

Storage:

In dry and cool places.The best condition is with temperature between 15℃ and 35℃,with a relative humidity between 30% and 70%.Before use,please kep it in original package.

Packaging Style:

Each roll is packed in a polyethylene bag inside,then outside with a cardboard box,then on pallet.

Packaging∇ivery:

Packaging Details:50kg/roll,cartons,pallet.

Delivery Detail:15-20 days after receive the advance payment

Company Information

Hebei Yuniu Fiberglass Manufacturing Co.,Ltd,established in 2012, is a professional fiberglass manufacturer in north China, which located at Guangzong County,Xingtai City, Hebei Province.China. As a professional fiberglass enterprise,mainly manufactures and distributes a wide range of E type fiberglass products, such as fiberglass roving,fiberglass chopped strands, fiberglass chopped strand mat,fiberglass woven roving, needled mat, fiberglass fabric and so on.These are widely used in construction industry, automotive industry, airplane and ship building area, chemistry and chemical industry, electrical and electronics, sports and leisure,the emerging field of environmental protection like wind energy, combination of varies of pipes and thermal insulation material.The E-glass products are compatible with the various resins,such as EP/UP/VE/PA and so on.

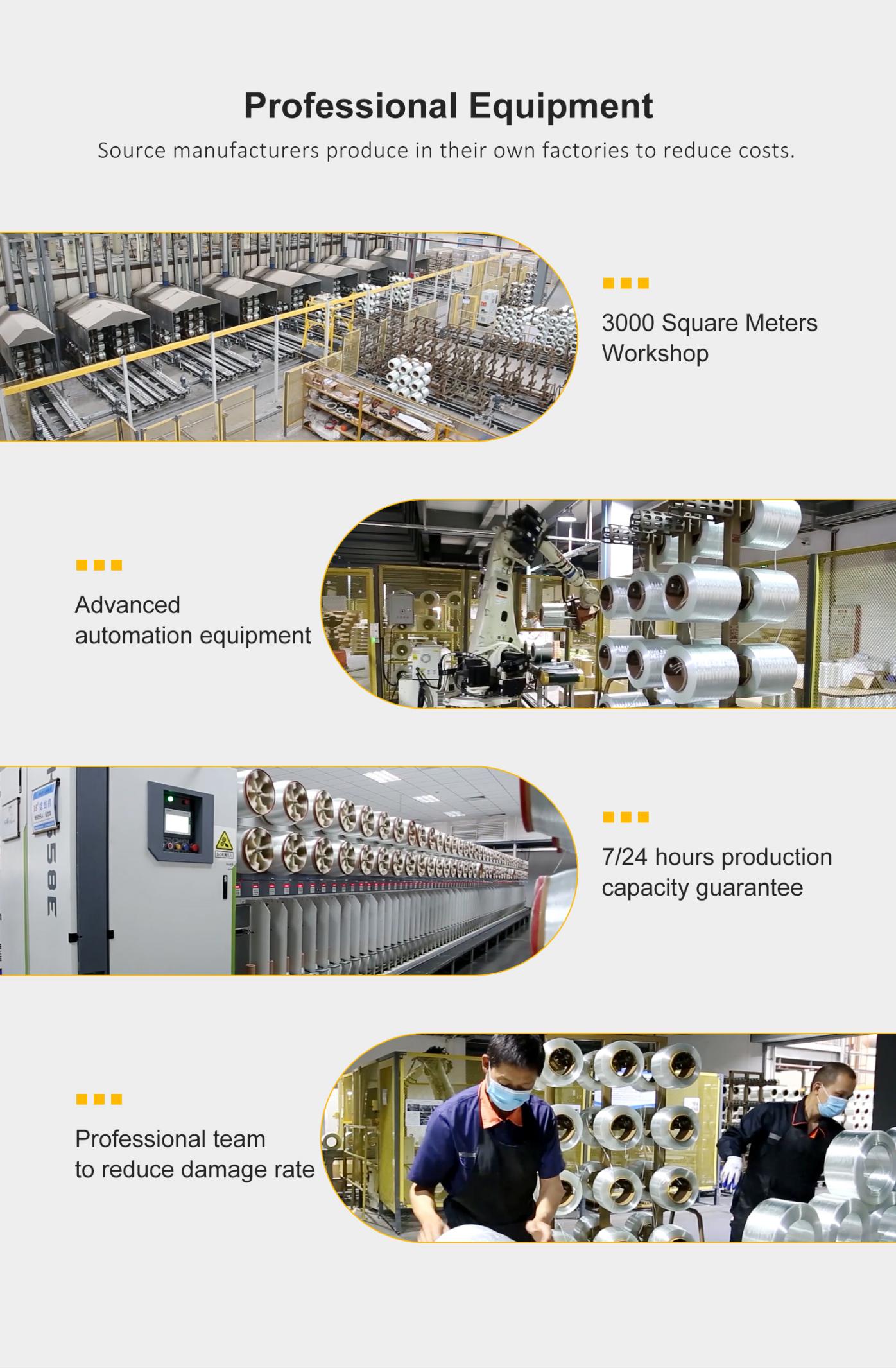

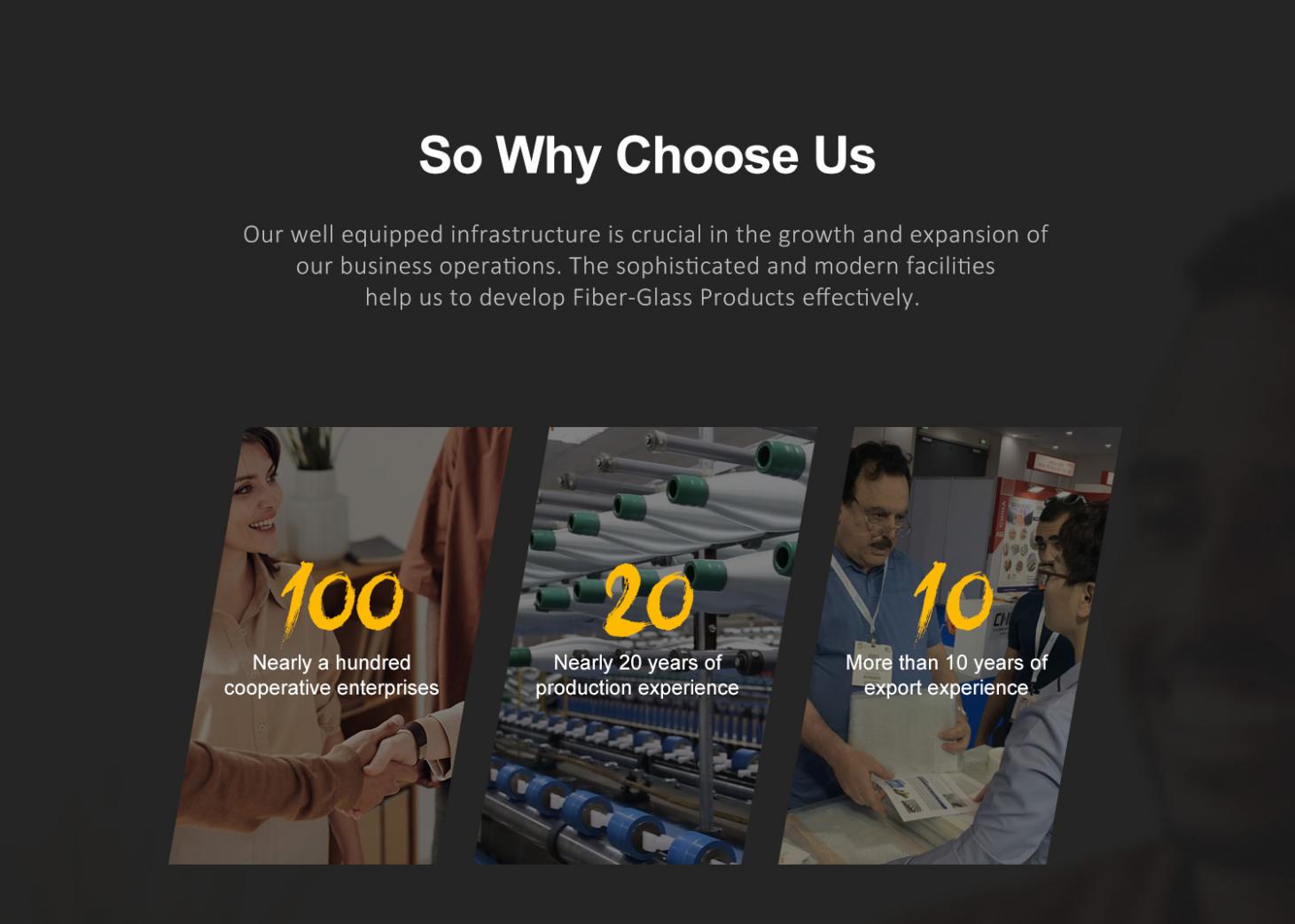

Our Advantage

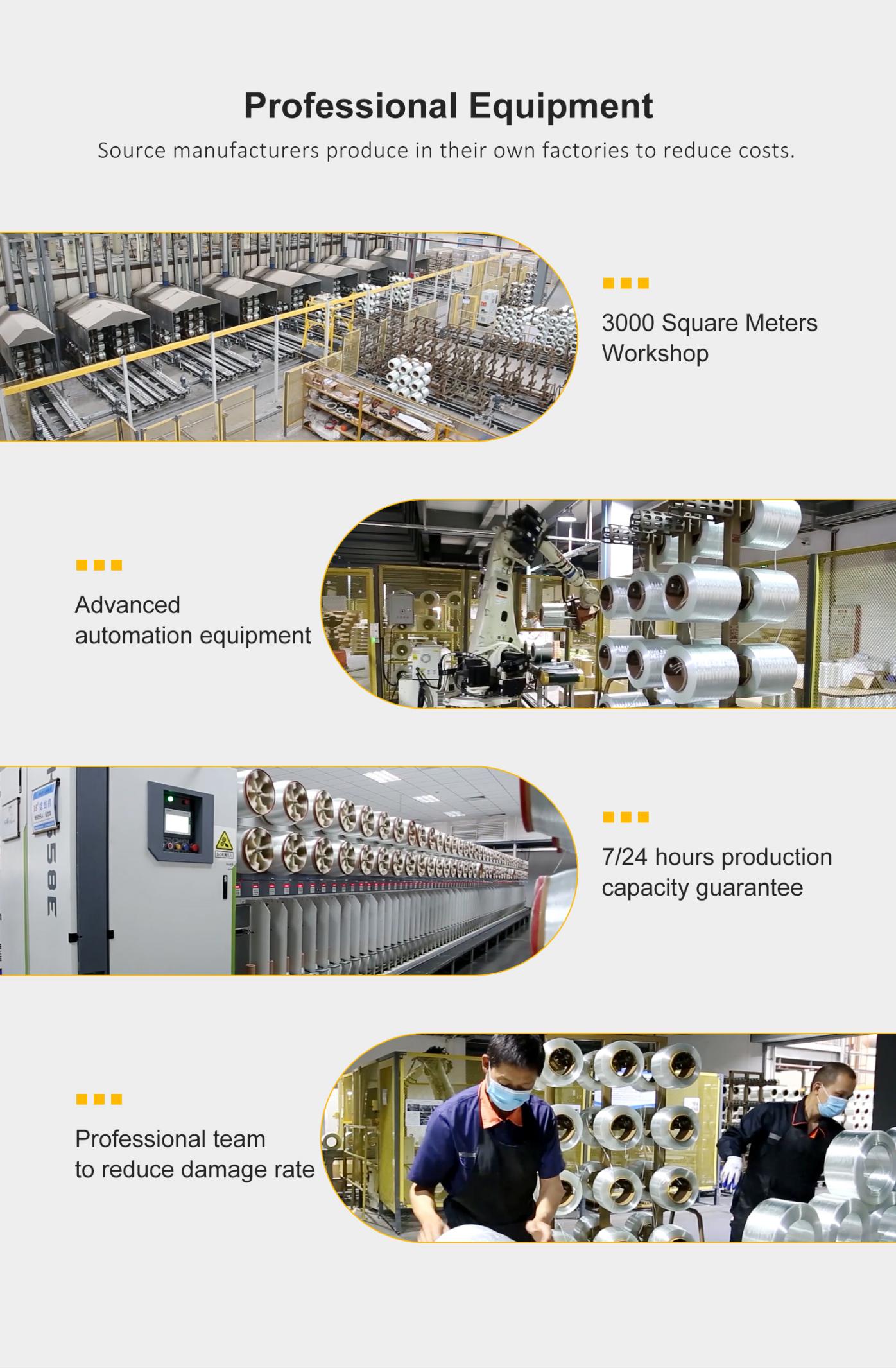

Our Advantage

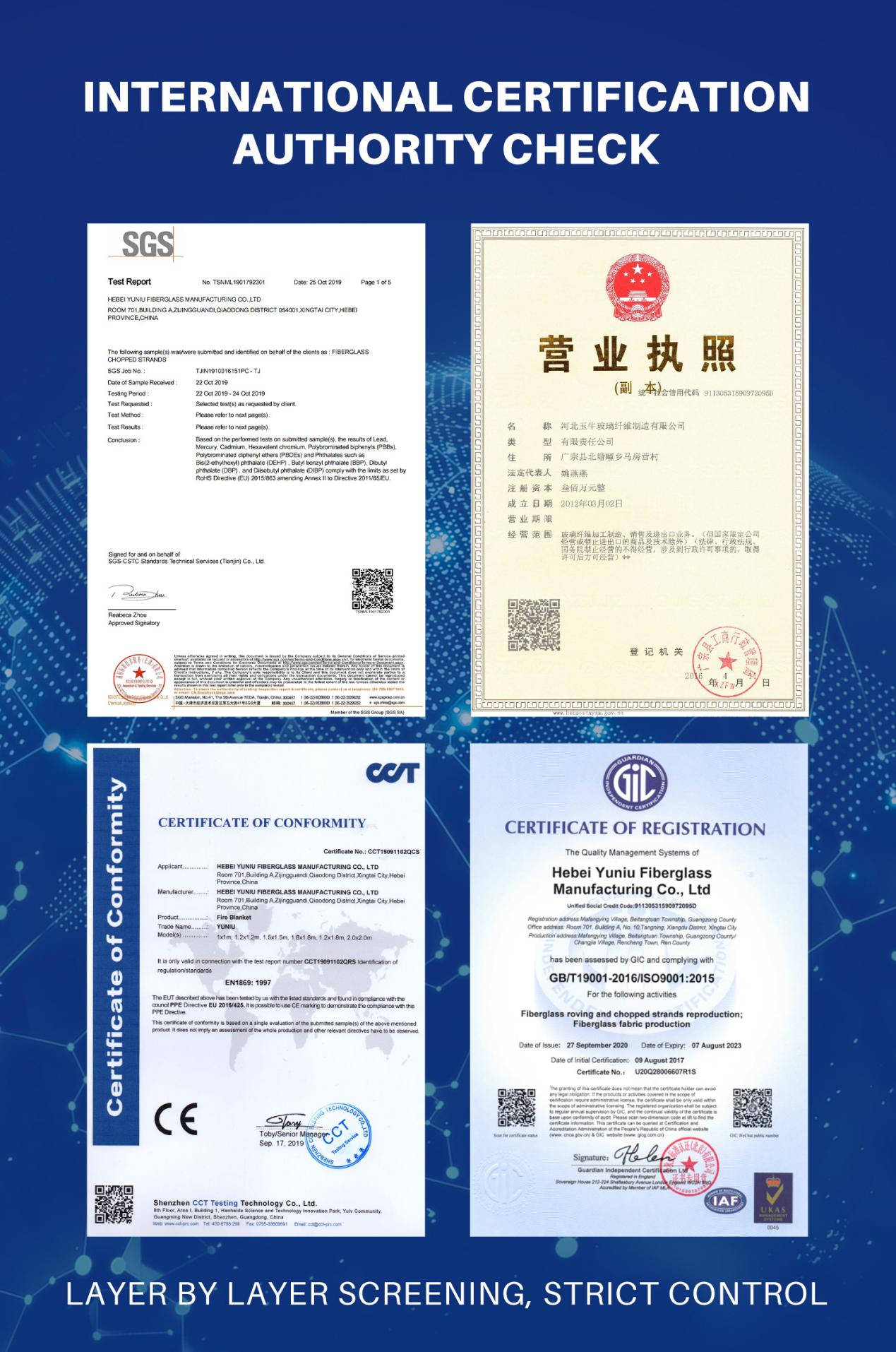

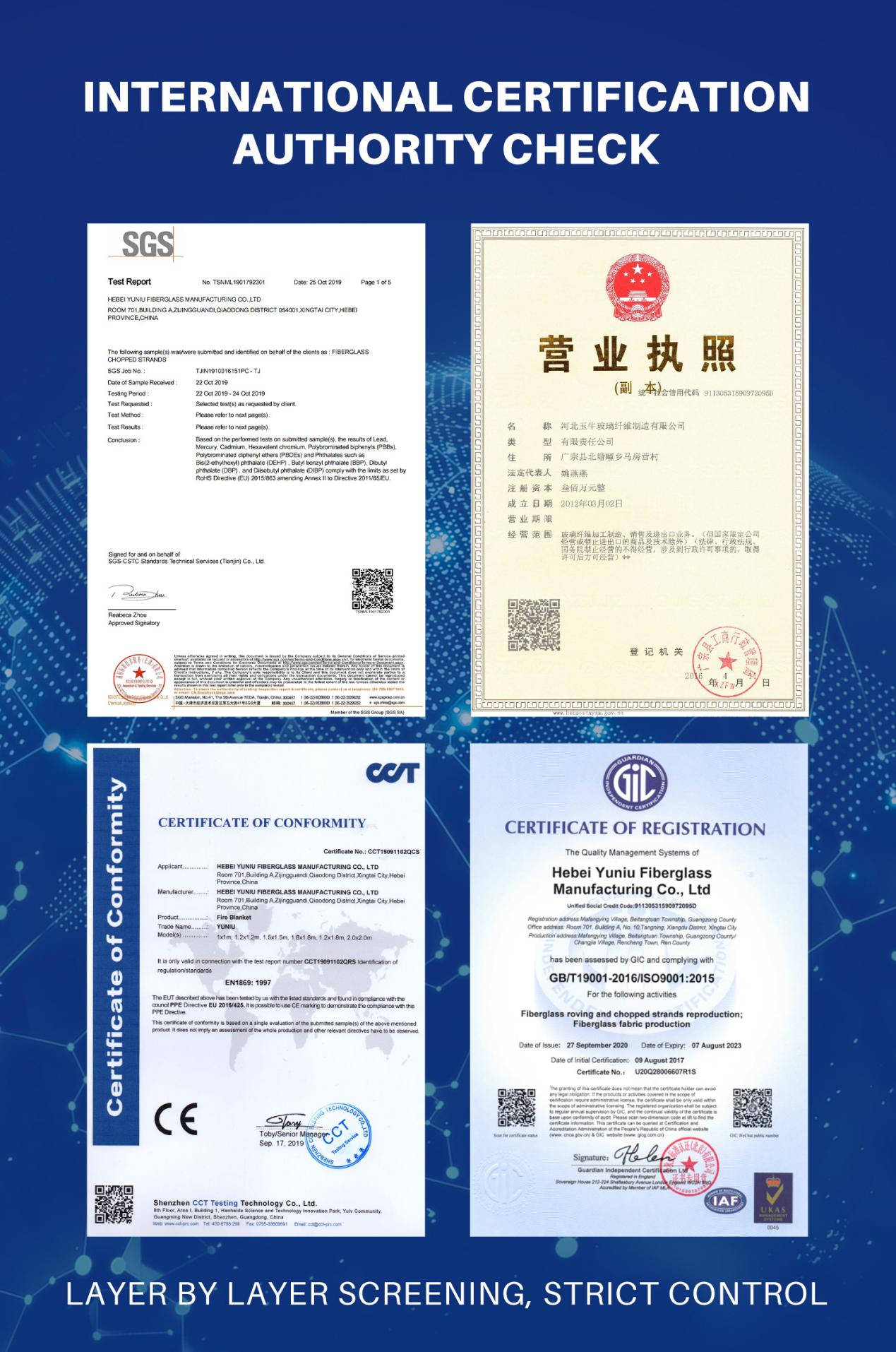

Our well equipped infrastructure is crucial in the growth and expansion of our business operations. The sophisticated and modern facilities help us to develop Fiber-Glass Products effectively. Our infrastructure is spread over a large area and is segregated into manufacturing unit, quality division and warehousing unit. Our manufacturing unit is equipped with special purpose machines and requisite tools & equipment. With the use of these machines, we are able to manufacture our products in bulk quantity and meet the requirements of our clients. We make sure that Fiber-Glass Products render high quality standards. Our quality controllers regularly monitor entire stage of production process to ensure the perfect quality of our products. We adhere to latest technology and quality control procedure, which ensures quality standards and specifications. The company is able to offer first class quality and main products with full trace-ability by BV,SGS and ISO9001. Therefore, you could rest assure our perfect quality and service.

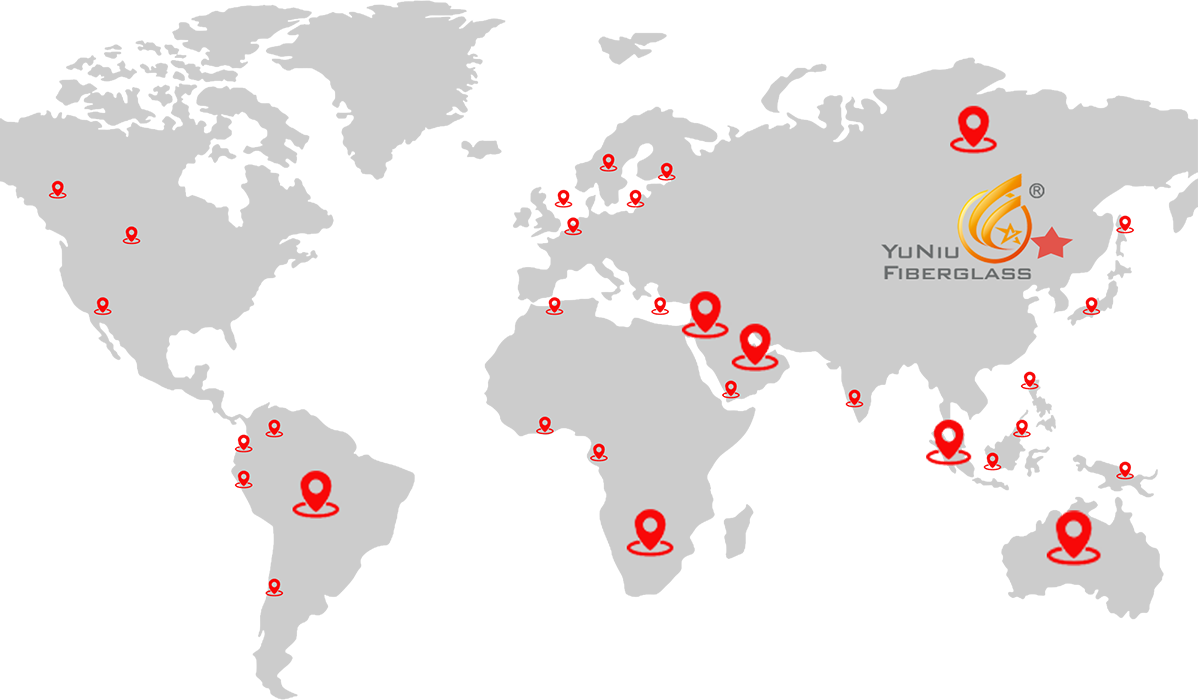

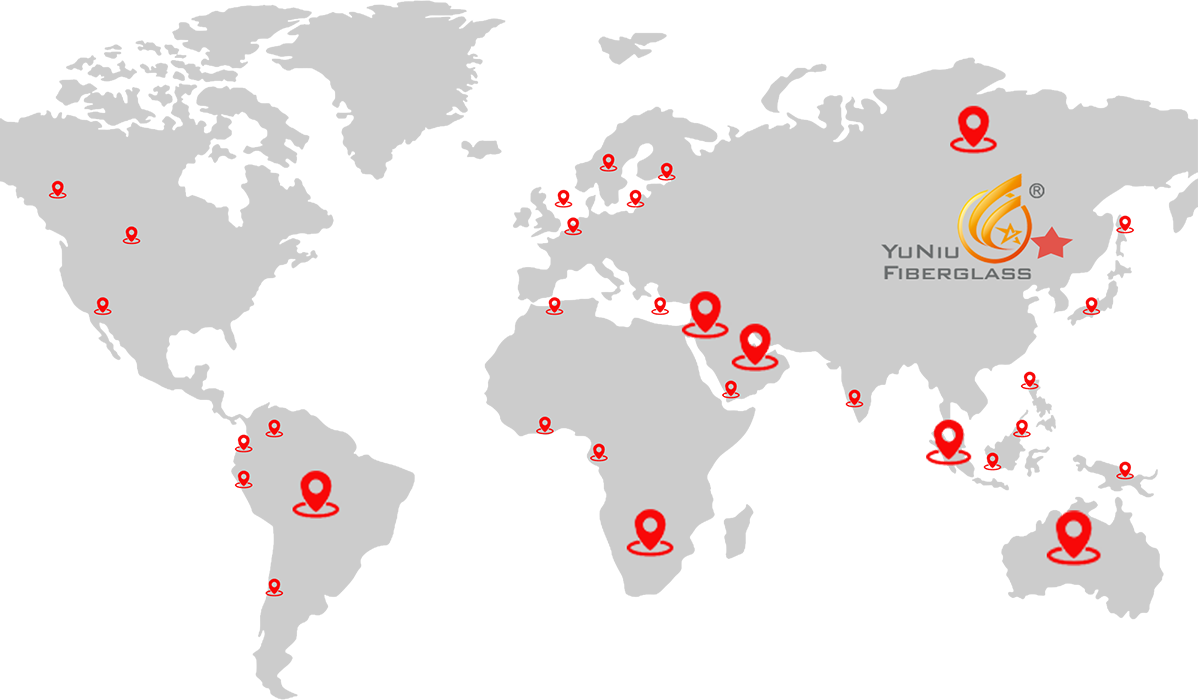

Our sales network

Products are sold to more than 126 countries and regions such as the United States, Europe, and Southeast Asia.

Q1:Are you a factory? Where are you located?

A: we are a manufacturer.

Q2:What's the MOQ?

A: Usually 1 Ton

Q3:Package & Shipping.

A: Normal package:carton(Incuded in the unite price)

Special Packge: need to charge according the actual situation.

Normal shipping :your nominated Freight forwarding.

Q4:When can I offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but you need to pay the freight charge.If you need a special size, We will charge the sample making fee which is refundable when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

HD Fiberglass Manufacturing

Your success is our business!

Any questions, please contact us freely.

fiberglass multiaxial fabric for boat building new product woven fiberglass cloth

Description:

Multi-Axial Fiberglass Fabric is a type of composite reinforcement material used in various industries, particularly in manufacturing composite structures. This fabric is characterized by its multi-axial construction, meaning it consists of layers of fiberglass fibers oriented in different directions.

The multi-axial construction of the fabric offers significant advantages in terms of strength and stiffness. The fibers are oriented in multiple directions, typically at 0°, 90°, and ±45° angles, which enhances the fabric's ability to withstand different types of loads, including tension, compression, and shear forces. This multidirectional reinforcement improves composite components' overall structural integrity and load-bearing capacity.

The 1708 Multi-Axial Fiberglass Fabric is commonly used in the construction of high-performance composite parts, such as boat hulls, automotive components, wind turbine blades, aerospace structures, and sporting goods. Its versatile nature allows for tailored reinforcement in specific areas, optimizing strength and minimizing weight.

Overall, the Multi-Axial Fiberglass Fabric is a reliable and widely used material in the composites industry, providing enhanced strength, stiffness, and versatility for a variety of applications.

Application:

It's compatible with UP,Vinyl Ester and Epoxy etc,used in GRP pultrusion process,hand lay-up process and RTM process etc,out-made products include GRP boats,automobile parts,wind energry blades etc.

How To Use Multi-Axial Fiberglass Fabric?

Prepare the surface: Ensure that the surface where the fabric will be applied is clean, smooth, and free from any contaminants that could affect adhesion or integrity.

Cut the fabric: Measure and cut the fabric to the desired shape and size using sharp scissors or a rotary cutter. Consider the specific requirements of your project and cut the fabric accordingly, allowing for any overlaps or seam allowances as needed.

Position the fabric: Place the cut fabric onto the prepared surface, aligning it with the desired orientation and direction of the fibers. The multi-axial construction of the fabric allows you to position it in various orientations to best suit your project's structural needs.

Apply resin: Once the fabric is properly positioned, impregnate it with an appropriate resin system. Commonly used resins include polyester, epoxy, or vinyl ester resins. Follow the instructions provided by the resin manufacturer regarding the mixing ratios, pot life, and application techniques.

Wet out the fabric: Apply the resin onto the fabric using a brush, roller, or squeegee, ensuring thorough saturation of the fabric. Work the resin into the fabric, ensuring that all layers are impregnated evenly. Take care to avoid excessive resin pooling or dry spots.

Consolidation and removal of air bubbles: After wetting out the fabric, consolidate the layers by using a consolidation roller or by applying vacuum pressure if applicable. This helps to remove any trapped air bubbles and ensures proper bonding between the fabric and the substrate.

Cure the composite: Allow the resin to cure according to the manufacturer's instructions. This may involve a specific curing time and temperature. Ensure proper curing conditions, such as temperature control and appropriate curing duration, to achieve optimal mechanical properties.

Post-processing: After the composite has cured, you can further process it as required. This may include trimming excess material, sanding or finishing the surface, or applying additional layers or coatings depending on your project's specifications.

Remember to follow safety guidelines, wear appropriate personal protective equipment, and consult the specific instructions provided by the fabric and resin manufacturers for best results.

General Specifications And Key Technical Data:

Specs | 0º(g/m2) | 90º(g/m2) | +45º(g/m2) | -45º(g/m2) | Mat(g/m2) | Total Weight(g/m2) |

EMF400/800(0º, 90º) | 400 | 400 | ---- | ---- | 400 | 1200 |

EMF1200(0º, +45º, -45º) | 400 | ---- | 400 | 400 | ---- | 1200 |

EMF800(0º, 90º, +45º, -45º) | 200 | 200 | 200 | 200 | ---- | 800 |

EMF450/800(0º, 90º, +45º, -45º) | 200 | 200 | 200 | 200 | 450 | 1250 |

Products feature and Advantages:

1)Mechanical property of different directions is adjustable.

2)The multi-layers structure could simplify forming process,improve operation efficiency.

3)Quickly wet-out,good molding property,easily to delete air bubbles.

Storage:

In dry and cool places.The best condition is with temperature between 15℃ and 35℃,with a relative humidity between 30% and 70%.Before use,please kep it in original package.

Packaging Style:

Each roll is packed in a polyethylene bag inside,then outside with a cardboard box,then on pallet.

Packaging∇ivery:

Packaging Details:50kg/roll,cartons,pallet.

Delivery Detail:15-20 days after receive the advance payment

Company Information

Hebei Yuniu Fiberglass Manufacturing Co.,Ltd,established in 2012, is a professional fiberglass manufacturer in north China, which located at Guangzong County,Xingtai City, Hebei Province.China. As a professional fiberglass enterprise,mainly manufactures and distributes a wide range of E type fiberglass products, such as fiberglass roving,fiberglass chopped strands, fiberglass chopped strand mat,fiberglass woven roving, needled mat, fiberglass fabric and so on.These are widely used in construction industry, automotive industry, airplane and ship building area, chemistry and chemical industry, electrical and electronics, sports and leisure,the emerging field of environmental protection like wind energy, combination of varies of pipes and thermal insulation material.The E-glass products are compatible with the various resins,such as EP/UP/VE/PA and so on.

Our Advantage

Our Advantage

Our well equipped infrastructure is crucial in the growth and expansion of our business operations. The sophisticated and modern facilities help us to develop Fiber-Glass Products effectively. Our infrastructure is spread over a large area and is segregated into manufacturing unit, quality division and warehousing unit. Our manufacturing unit is equipped with special purpose machines and requisite tools & equipment. With the use of these machines, we are able to manufacture our products in bulk quantity and meet the requirements of our clients. We make sure that Fiber-Glass Products render high quality standards. Our quality controllers regularly monitor entire stage of production process to ensure the perfect quality of our products. We adhere to latest technology and quality control procedure, which ensures quality standards and specifications. The company is able to offer first class quality and main products with full trace-ability by BV,SGS and ISO9001. Therefore, you could rest assure our perfect quality and service.

Our sales network

Products are sold to more than 126 countries and regions such as the United States, Europe, and Southeast Asia.

Q1:Are you a factory? Where are you located?

A: we are a manufacturer.

Q2:What's the MOQ?

A: Usually 1 Ton

Q3:Package & Shipping.

A: Normal package:carton(Incuded in the unite price)

Special Packge: need to charge according the actual situation.

Normal shipping :your nominated Freight forwarding.

Q4:When can I offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but you need to pay the freight charge.If you need a special size, We will charge the sample making fee which is refundable when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 7 days ; if without the stock, need 7~15 days !

HD Fiberglass Manufacturing

Your success is our business!

Any questions, please contact us freely.