Email: info@hdfiberglass.com Whatsapp: +86 18833998929

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-04-04 Origin: Site

Did you ever wonder how the marvels of modern engineering manage to stay strong, lightweight, and durable all at once? Ever pondered over the secret behind structures that withstand harsh conditions without breaking a sweat? Enter biaxial fiberglass – the unsung hero in the world of composite materials.

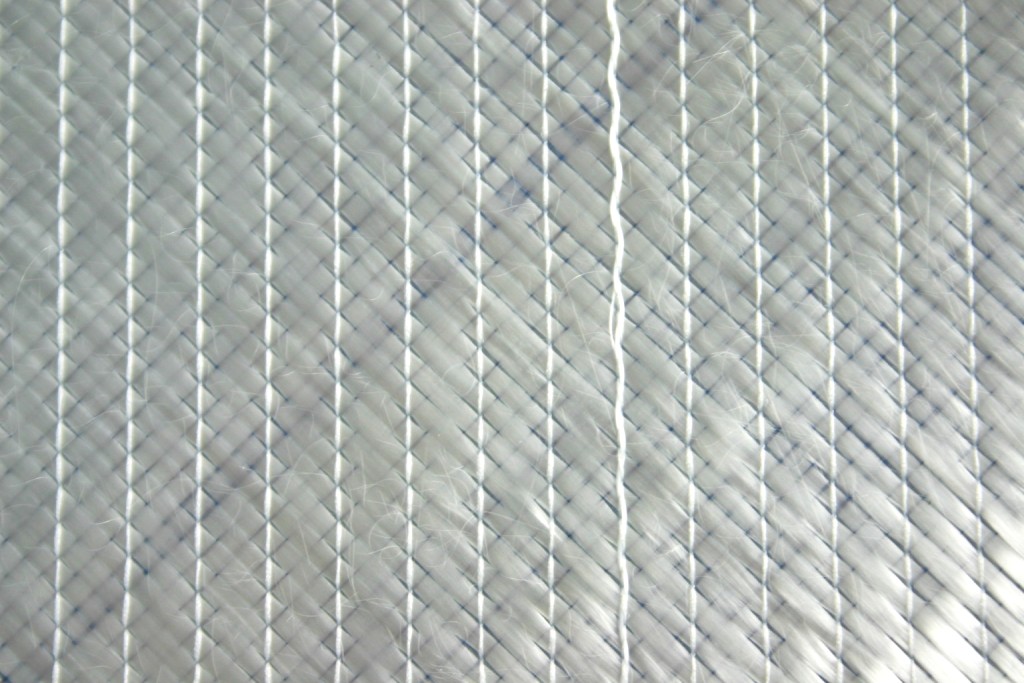

Biaxial fiberglass, in essence, is a fabric crafted by weaving strands of fiberglass together in two directions – typically at right angles to each other. This ingenious construction grants it remarkable strength and flexibility simultaneously, making it a go-to choice for a myriad of applications in various industries.

Curious to learn more about its versatility and impact? Let's delve deeper.

From aerospace to automotive, marine to construction, biaxial fiberglass finds itself indispensable in a multitude of fields. Its unique structure allows it to conform to complex shapes while providing exceptional strength, making it an ideal candidate for reinforcing composites.

In boat building, biaxial fiberglass helps create lightweight yet sturdy hulls, ensuring vessels can navigate rough waters with ease. In automotive manufacturing, it reinforces body panels, enhancing crash resistance without compromising on weight or design. In infrastructure projects, such as bridges and buildings, it reinforces concrete, extending the lifespan of structures while minimizing maintenance needs.

The applications are as diverse as they are vital, showcasing biaxial fiberglass's prowess in enhancing performance across industries.

When it comes to specifying biaxial fiberglass, numbers matter. Take, for instance, the commonly used 1708 biaxial cloth – a staple in many composite applications. The "1708" designation refers to its weight in grams per square meter (gsm) and its unique arrangement of strands.

A 1708 biaxial cloth typically measures around 1.45 millimeters (mm) in thickness, offering a balance between structural integrity and flexibility. This moderate thickness ensures it can conform to contours while providing ample reinforcement, making it a versatile choice for various projects.

With this understanding, engineers and manufacturers can precisely tailor their designs to meet specific performance requirements, knowing they have the right material for the job.

In the realm of fiberglass fabrics, the terms "biaxial" and "triaxial" often spark curiosity about their differences and applications.

Biaxial fiberglass consists of two layers of fibers oriented at right angles, offering strength along two primary axes. Triaxial fiberglass, on the other hand, adds a third layer of fibers, typically placed at a 45-degree angle to the primary two, enhancing stiffness and torsional resistance.

While both fabrics excel in reinforcing composites, their choice depends on the specific demands of the project. Biaxial fabrics are preferred for applications where flexibility and conformity are paramount, while triaxial fabrics shine in projects requiring enhanced stiffness and multidirectional strength.

Understanding these distinctions empowers engineers and manufacturers to select the most suitable fiberglass fabric for their intended application, ensuring optimal performance and durability.

What are the advantages of using biaxial fiberglass?

Biaxial fiberglass offers a plethora of advantages, including high strength-to-weight ratio, excellent conformability, corrosion resistance, and ease of handling. Its versatility makes it a preferred choice across diverse industries.

Can biaxial fiberglass be used for structural applications?

Absolutely! Biaxial fiberglass is commonly employed in structural applications, reinforcing composites to withstand heavy loads and harsh environments. Its superior strength and flexibility make it a reliable choice for structural enhancements.

In essence, biaxial fiberglass stands as a testament to human ingenuity and innovation. Its unparalleled strength, flexibility, and adaptability make it a cornerstone in various industries, from aerospace to construction. As we continue to push the boundaries of what's possible, biaxial fiberglass remains a steadfast ally, enabling us to build a future that's stronger, safer, and more resilient.

The darling of the electronic/industrial field - alkali-free fiberglass yarn

Exploring the Applications of SMC Materials in the Electrical Field

Steps for Applying Fiberglass Mesh to Walls for Reinforcement

Carbon Fiber Applications in the Field of Mass Transit: Revolutionizing Rail Travel?

What processes can fiberglass chopped strand mat be used for?